|

The original method is to use the BVM “Air Fill Chuck”

that is safety wire retained to an air pump as shown

here. You must thread the knurled end of the chuck

onto the Air Fill Valve in the model. Note that the safety wire wrap is

covered with electrical tape.

|

|

| |

|

An alternate and faster method to inject air into the

model’s storage tank (s) is to use a 2nd Air

Fill Valve (BVM#5758) (threaded into and stays with the

Air Fill Chuck) with a piece of BVM Heavy Duty Air

Line (a 3-5” piece) fitted to the Air Fill Valve on the

pump side. |

| |

|

|

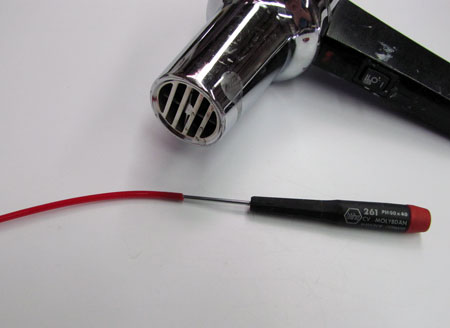

Use a razor to put a slight angle on the open end of

the airline to help guide it into the Air Fill Valve in

your model. Because of the slight variations of the

tubing O.D. and the Air Fill Valve I.D., the tubing may

be a loose fit.

|

|

| |

|

|

To adjust the O.D. end of the tubing, push it onto a

2mm diameter steel shaft such as this Wiha 261 x 40

Phillips Driver, then heat it with a heat gun.

|

|

| |

|

|

After it cools the tubing should fit snugly into the

model’s Air Fill Valve. Our tests showed that the

“perfect fit” withstood warm and cool ambient

temperatures. |

| |

|