F-100 D Hot Shots |

Jet Foam Cradle |

Fuel System Flush Mount

Fitting |

Kit Addendums | Major Kit Components | Structure

Highlights |

F-100 in a Jet Case | Color Schemes | Super

Scale Features| F-100 Landing Gear |

Recent flights & video | Wing Fences | Refueling Probe &

Pitot Tube | Cockpit

Gearing up your F-100 | Recent Updates | F-100 Sport Flying | Flying the REAL F-100F | Customers with

their F-100's

Specifications

LENGTH: 83.5"

WING SPAN: 69"

WING AREA: 1200 + sq. in.

WEIGHT: 29-31 lbs

SCALE: 1:6.75 or slightly larger than 1/7th scale

The model is sized to operate with a JetCat

P-120 or 160, AMT Pegasus, or RAM 1000 engine and weigh about 27 to 29 pounds.

Wing area is over 1,200 square inches.

We reverse engineered a real bone yard F-100D to produce

an exact scale outline model - something that any scale jet enthusiast would be

proud to own.

The

F-100D is very easy to assemble and service and despite its size, it completely

disassembles to fit into the BVM JET-CASE, making it very easy to transport.

|

See how the first flights went on the F-100.

Major Kit

Components

All components are composite except the

flaps. Flaps are built at the factory with hinges installed. Leading edge slat

tracks are factory installed for easy finishing. Stabs are checked for perfect

alignment on a surface plate and shipped bolted together as shown

above.

F-100 Super Sabre

Scale Outline

Accuracy is important |

The real

test for "accuracy of outline" is placing your model in front of Top Gun judges

- they rarely miss a detail.

Most of

these judges have years of experience at Top Gun making them the most critical

and yet consistent in the business. That is why we are very pleased with their

comparison of the BVM F-100D to the 3-view drawings as printed in the War Paint

Series #4 book on the North American Super Sabre.

The model received 29.25 out of a possible 30.00 points for accuracy

of outline. This means that the basics are there for a serious scale

enthusiast. An owner of a BVM F-100 can feel confident that his efforts to

finish and detail his jet will not be in vein when it's time to put it in front

of the judges.

The Inlet opening

The relatively small opening and sharp lip of the F-100 inlet

prohibited its accurate scale modeling prior to turbine power. This and other

details like the 20mm gun recesses are faithfully reproduced in the BVM

moldings. Note also in this low angle view how prominent the leading edge slats

are in the extended position.

The inlet of the F-100 must be right or the whole front of the

fuselage suffers. Since we had access to a real F-100, we actually put a

plywood plate, covered with poster board, over the front of the aircraft's

inlet and traced it. We then used our "Faro" digitizing arm to record the X-Y

components into our AutoCAD system and accurately reproduce it to the 1:6.857

scale of the BVM model.

The Boneyard

F-100

Serious scale modelers would give anything to have access to the

real thing - especially one that was disassembled. We were lucky to find an

F-100D in just this condition in Florida, and we visited the site 4 times with

camera's, measuring equipment, a ladder and drawing supplies to be able to

reverse engineer the airframe.

This investment of time at the onset of the project pays off in the

long run because the investment in the production tooling is secure.

Customer confidence and satisfaction that he

has an accurate model is the ultimate reward.

F-100 Flight

Scores

The highest in Designer

Scale

Jeff Foley (1st with an BF-109E) and Nick Ziroli Jr (2nd with an

Avenger) had the edge in static scoring and they deserved it. The time and

experience these guys put into their models must be matched if you want to beat

them because they both fly very well too.

The top 3 places in this tough category were separated by less than

1/4 of a point as shown by their scores 1st - 191.541, 2nd - 191.375, 3rd -

191.333.

I was pleased that the

F-100 could score so well in the flight category - it has the smoothness and

performance to be a winner, especially in crosswind conditions. |

F-100 Super Sabre

Super Scale

Feature

"Thin Flying Surfaces" |

The F-100 was the first

operational jet fighter for the U.S. Air Force that was designed to operate

supersonic. Experienced gained by the early X plane development programs

allowed North American to design and build very thin, low drag flying surfaces

that could also withstand the stresses of MACH 1 plus flight. The F-100 was the first

operational jet fighter for the U.S. Air Force that was designed to operate

supersonic. Experienced gained by the early X plane development programs

allowed North American to design and build very thin, low drag flying surfaces

that could also withstand the stresses of MACH 1 plus flight.

We had

access to a bone yard F-100 that we reverse engineered to design the BVM model.

When we first measured the thickness (or better, the thinness) of the flying

surfaces, we knew we had a challenge.

We also knew that to build

them "fat" would certainly be easier, but not scale or authentic looking. Our

philosophy was; why go to all the trouble and expense to build the tooling and

then have to look at a fat wing, stab and fin with

disappointment.

As we mentioned earlier,

the scale NACA 64A007 airfoil was used for the wing along with operational

leading edge slats to make the thin wing act like it is fat for take-off

and landing.

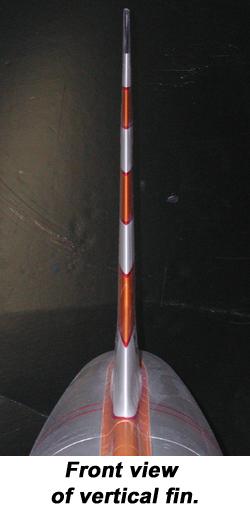

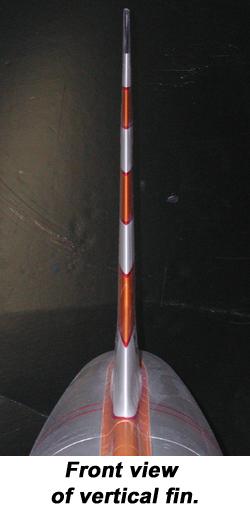

The fin, fin base on the fuse and the stabilators offered

some special challenges to duplicate those sharp leading and trailing

edges and

the overall thinness ratio of the surfaces. edges and

the overall thinness ratio of the surfaces.

Thanks to super materials

like Carbon Fiber and Titanium we were able to meet the engineering challenges

and produce light weight, truely scale, supersonic looking flying surfaces that

have demonstrated their air worthiness many times at 200+ m.p.h.

speeds.

|

"Thin is in"

on a

real jet fighter |

F-100 D Fine Feature

Super Scale Undercarriage |

|

Every

truly scale jet needs a scale landing gear made exclusively for it or it just

won't look convincing or function properly. That's what we have learned over

the years at BVM.

The

capability to design and manufacture such items can only come from a mature

company that has acquired the skills and equipment to do so. This beautiful and

functional landing gear system for our F-100D reflects that capability.

Flight testing has allowed us to fine tune the

design and present to the customer a system that he will be proud to

own.

Since we all occasionally

"prang one in", parts and service are extremely important. Again, it takes a

mature company to be able to back up the product for many years to

come.

|

|

|

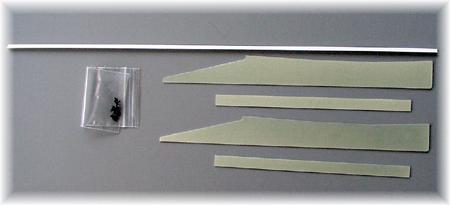

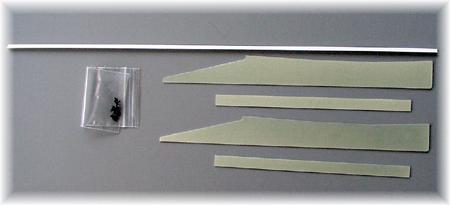

F-100 Wing Fences

optional

parts

|

Most

F-100D's had wing fences applied to the upper outboard sections. The exact

location is determined by the molded dots in the top wing skin. Most

F-100D's had wing fences applied to the upper outboard sections. The exact

location is determined by the molded dots in the top wing skin.

BVM has machined the fences and a base strip

from .030" poly ply and provided a plan and brief instruction sheet to make the

installation easy. The fence base strip is attached with 4 panel screws each

allowing removal for Jet Case transport. BVM has machined the fences and a base strip

from .030" poly ply and provided a plan and brief instruction sheet to make the

installation easy. The fence base strip is attached with 4 panel screws each

allowing removal for Jet Case transport.

|

|

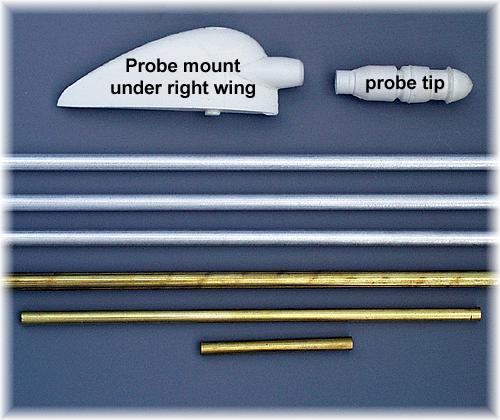

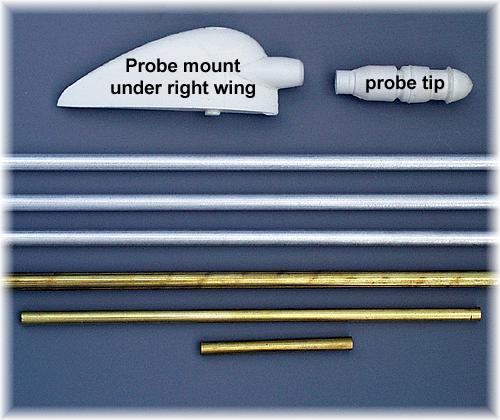

F-100 Refueling Probe & Pitot

Tube

|

F-100's had both straight and bent refueling

probe's. To replicate the bent version, apply an extension spring (tight

winding) to the O.D. of the tube. Use the drawing (included) to locate the

bends.

|

|

|

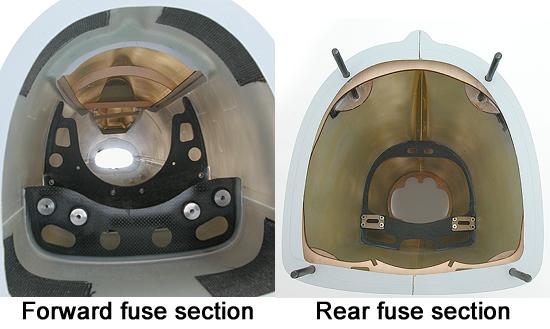

F-100 in a Jet Case |

|

It took

some planning in the early stages of developing the F-100 to allow it to be

transported in our UPS and Airline acceptable "Jet Case". Notice that the aft

fuse section fits over the nose of the forward section and that the wing flaps

are removed. Even the aft wing spars were shaped to conform to the molded

fiberglass container.

Careful

wrapping of the parts in a high density foam allows all but the hot section

tailpipe to be safely air freighted to your destination. A separate cardboard

tube can be used to send the tailpipe and external stores.

Transportability is another great reason to

own a BVM F-100D. |

PRICING

| JET KIT |

| 9700 |

F-100 D |

$4,925.00 |

| |

includes -

airframe (all composite) with hardware, cockpit deck,

plans & instructions. |

|

| |

|

|

|

LANDING GEAR SYSTEM |

|

| 9710 |

Landing Gear System

(complete) |

$2,397.75 |

| |

includes -

retracts, air install package w/door cylinders, struts,

wheels, brakes, and Smooth Stop brake valve. |

|

| |

|

|

|

TURBINE INSTALLATION KITS |

|

|

All turbine installation kits include BVM Bypass system,

S.S. tailpipe (double wall), S.S. augmenter, and

hardware. |

|

| |

JetCat P-180 RX

|

$685.00 |

| |

Jet Central Cheetah |

$625.00 |

| |

Jet Central Rhino |

$685.00 |

| |

KingTech K-180G |

$685.00 |

| |

|

| FUEL

CELLS |

|

| 6105 |

Kevlar Kerosene Fuel

Cells |

$450.00 |

| |

|

|

| |

| Options:

|

| 1955 |

F-100 Aft Hot Section paint kit |

$72.50 |

| 9720 |

Wing Tanks - pair |

$425.00 |

| 9725 |

Pylon kit (complete set of 6) |

$525.00 |

| 9727 |

Inboard pylons (2) |

$185.00 |

| 9728 |

Midwing pylons (2) |

$175.00 |

| 9729 |

Outboard pylons (2) |

$185.00 |

| K9700-50 |

Cockpit detail kit |

$334.95 |

| 9565 |

Aeropoxy glue kit |

$87.95 |

| |

Includes - glue gun, 2

glue cartridges, 2 long nozzles and 2 short nozzles |

|

| 9735 |

Wing Fences - pr |

$27.95 |

| 9737 |

Molded Refueling Probe and Pitot

Tube |

$62.00 |

| 650 |

Jet Case (f/g molded) |

$629.00 |

| |

|

|

|

PRICES SUBJECT TO CHANGE WITHOUT NOTICE AND APPLY TO

SALES WITHIN USA ONLY.

Bob Violett Models Inc. 3481

State Road 419 Winter Springs, Florida 32708

USA tel 407-327-6333 fax 407-327-5020

www.bvmjets.com |

F-100

Airframe Directive (A.D.)

And other helpful notes

Large Fuel Cell Transfer

Tubes

Replace Brass with Stainless Steel

(4/20/06)

There has been one case where the brass

tube that transfers fuel through a hole in the fuel cell baffle experienced

a razor saw-like cut. The engine flamed out because the remaining fuel below

the tube was unusable. There has been one case where the brass

tube that transfers fuel through a hole in the fuel cell baffle experienced

a razor saw-like cut. The engine flamed out because the remaining fuel below

the tube was unusable.

The most likely cause of the brass tubing

failure was many miles of trailer transport of the model with the fuel cells

empty. The most likely cause of the brass tubing

failure was many miles of trailer transport of the model with the fuel cells

empty.

The Fix

BVM

now supplies Stainless Steel tubes with the large baffled fuel cells i.e., KingCat,

F-100, F-4, Rafale, F-86 (80"). Retrofit parts are available. Ask for part

#PS-TU-0003 (quantity 2) price $5.00 for the pair. BVM

now supplies Stainless Steel tubes with the large baffled fuel cells i.e., KingCat,

F-100, F-4, Rafale, F-86 (80"). Retrofit parts are available. Ask for part

#PS-TU-0003 (quantity 2) price $5.00 for the pair.

To

be honest, we don't know how many travel miles the brass tubes will withstand.

It could vary quite a bit. BVM is converting our factory demo models as time

allows. Our prototype F-100D is 6 years old, has at least 300 flights and more

trailer miles than we can count. We inspected the brass tubes and found minimum

wear. We changed them to the Stainless Steel variety anyway. To

be honest, we don't know how many travel miles the brass tubes will withstand.

It could vary quite a bit. BVM is converting our factory demo models as time

allows. Our prototype F-100D is 6 years old, has at least 300 flights and more

trailer miles than we can count. We inspected the brass tubes and found minimum

wear. We changed them to the Stainless Steel variety anyway.

Wing Pylon Mounting

- Locate drill locations per plans.

- Drill pilot holes with 1/8” bit. be sure to

align drill vertically with respect to ground stance of model. (not surface of

wing skin).

- Re-drill with 3/16 bit, then with 13/64” bit.

(hole size is critical for proper installation of brass insert.)

- Install brass insert onto 4-40 socket head bolt.

Slowly thread insert into hole. Maintain vertical alignment to avoid braking

maple block loose in wing.

- Remove bolt from insert, if insert does not

release, place a drop of water into hole to swell maple block around insert.

Wait 10 minutes, then try to remove bolt again. If needed, a drop of ZAP can be

used to hold insert in position in block.

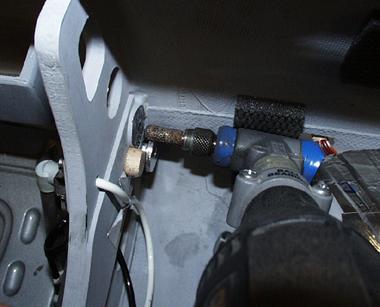

F-100D & F

Stab Servo Arms

The details and instructions on the top

view of the fuse plans show and emphasis that the stab pushrod clevises are

connected to the 2nd hole from the center of the JR 215 heavy duty arms.

THIS IS CORRECT. The details and instructions on the top

view of the fuse plans show and emphasis that the stab pushrod clevises are

connected to the 2nd hole from the center of the JR 215 heavy duty arms.

THIS IS CORRECT.

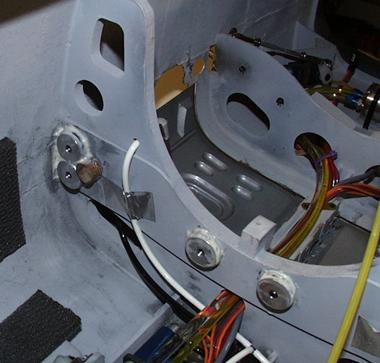

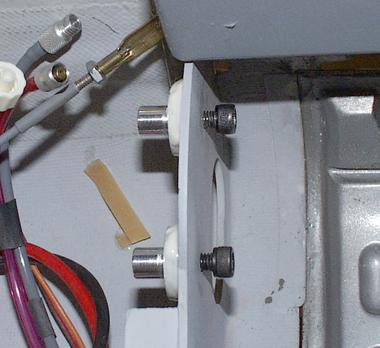

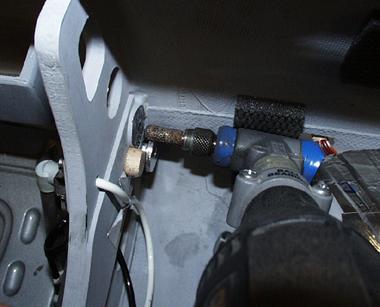

The photo on page 54 of the "D" model and page 63 of the "F" model

should be replaced with this image. The photo on page 54 of the "D" model and page 63 of the "F" model

should be replaced with this image.

Trailer Transporting

the "Heavy

Jets"

It is convenient to transport the F-100

and F-4 gear down and strapped to shelves in the trailer. However, we are

seeing some wear and tear on the wing mounting formers in the fuselage. The

#10-32 bolts are working loose and even stripping the threads on the carbon

fiber threaded discs. Of course, occasional stiff landings further aggrivate

this problem. It is convenient to transport the F-100

and F-4 gear down and strapped to shelves in the trailer. However, we are

seeing some wear and tear on the wing mounting formers in the fuselage. The

#10-32 bolts are working loose and even stripping the threads on the carbon

fiber threaded discs. Of course, occasional stiff landings further aggrivate

this problem.

Supporting the model on foam rubber on the trailer shelf should

greatly alleviate the problem. Supporting the model on foam rubber on the trailer shelf should

greatly alleviate the problem.

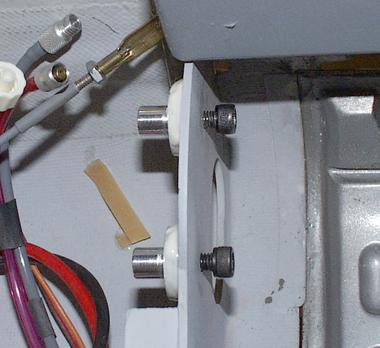

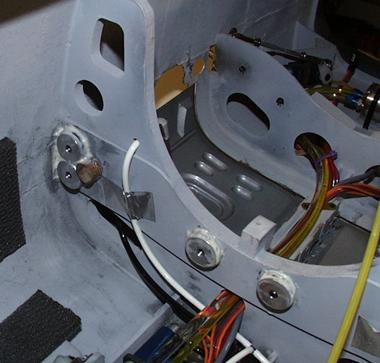

To fix a stripped out receptacle we made some aluminum

threaded inserts. See photo's for how to attach. To fix a stripped out receptacle we made some aluminum

threaded inserts. See photo's for how to attach.

To add the threaded

aluminum inserts (BVM #2880) to the rear wing mounting formers, first scuff

with #80 grit, tack with slow CA, then surround with Aeropoxy.

Use a 90° Dremel

tool and a Perma-Grit RF-5C to open holes in the forward wing mount former to

accept the aluminum insert shaft. Accomplish one at a time, checking alignment

with wing attached.

You should also

periodically check the 4-40 bolts that attach the main gear to the carbon fiber

wing spars.

F-100 Rudder Trim

It is hard to observe at a glance

because of the scale bulge in the fin at the top of the rudder and because the

rudder is thicker than the fuse fairing at the bottom. Take a close look before

take-off. It is hard to observe at a glance

because of the scale bulge in the fin at the top of the rudder and because the

rudder is thicker than the fuse fairing at the bottom. Take a close look before

take-off.

F-100 Tailpipe Cooling Shroud

A few of the very early kits may need

to have this part updated. The correct exit diameter at the rear of the outer

pipe is 3-3/4". If yours is less, return it for a no charge upgrade. The

upgrade deletes the need to wrap the outside of the pipe with the heat blanket.

The new system runs cooler. A few of the very early kits may need

to have this part updated. The correct exit diameter at the rear of the outer

pipe is 3-3/4". If yours is less, return it for a no charge upgrade. The

upgrade deletes the need to wrap the outside of the pipe with the heat blanket.

The new system runs cooler.

F-100 Flap Geometry Improved

A second look at the flap linkage

produced better results. It uses all of the same parts but realizes a better

advantage in both the up and full down position. A second look at the flap linkage

produced better results. It uses all of the same parts but realizes a better

advantage in both the up and full down position.

As with any control surface linkage system, be

sure that the surface will travel freely beyond the prescribed limits so that

the servo is not under heavy load while commanding the desired deflection. For

the F-100 flaps, this means that the inboard ends do not bind on the fuselage

sides. Use a volt/amp meter to check for excess servo power drain. As with any control surface linkage system, be

sure that the surface will travel freely beyond the prescribed limits so that

the servo is not under heavy load while commanding the desired deflection. For

the F-100 flaps, this means that the inboard ends do not bind on the fuselage

sides. Use a volt/amp meter to check for excess servo power drain.

The system shown has been

thoroughly flight tested in our F-100F. The system shown has been

thoroughly flight tested in our F-100F.

Note servo arm angle with flaps

full up. Clevis is in 1st hole of JR heavy duty servo arm and the 2nd hole on

the metal flap horn. Do not neglect the wood shim, flaps up stop

(arrow).

Note angle of the servo arm in the

flaps down position.

Installing the Slats

Steven Ellzey is a super precise

craftsman as well as being an Aerospace engineer, so I am sure F-100 builders

can benefit from his slat technique. Steven Ellzey is a super precise

craftsman as well as being an Aerospace engineer, so I am sure F-100 builders

can benefit from his slat technique.

Steven says:

I finished up getting the

slats on the Hun, and they turned out working very smoothly (if you pick the

wing up leading edge down they will fall on the floor). I thought I would pass

on what I did, should it be of any help. I finished up getting the

slats on the Hun, and they turned out working very smoothly (if you pick the

wing up leading edge down they will fall on the floor). I thought I would pass

on what I did, should it be of any help.

For fitting and gluing, a

layer of masking tape was applied to each side of the rails where they go into

the wing. This forced the rail to the center of the slot. The opening into the

spar on the slat was made a bit over sized, and the top of the rail, where it

meets the slat, was cut back a bit extra (1/64"). This was done so that when

the slat was held in place it would not touch, and possibly bend, the rails.

The slat was held in place by several pieces of balsa, CA'ed to masking tape

(see attached photos). This made sure that the OML (outer most layer) of the

slat matched the OML of the wing on the top. I also applied a thin layer of CA

to the edges of the rails where they go into the wing and polished it with 600

grit. I did this after the fact on one side and it seemed to help a bit when

the slat was loaded vertically. On the other side, I CA'ed and polished before I

glued them in (much easier). Other than the CA and polishing on the first side,

no work was done on the rails after being glued in. For fitting and gluing, a

layer of masking tape was applied to each side of the rails where they go into

the wing. This forced the rail to the center of the slot. The opening into the

spar on the slat was made a bit over sized, and the top of the rail, where it

meets the slat, was cut back a bit extra (1/64"). This was done so that when

the slat was held in place it would not touch, and possibly bend, the rails.

The slat was held in place by several pieces of balsa, CA'ed to masking tape

(see attached photos). This made sure that the OML (outer most layer) of the

slat matched the OML of the wing on the top. I also applied a thin layer of CA

to the edges of the rails where they go into the wing and polished it with 600

grit. I did this after the fact on one side and it seemed to help a bit when

the slat was loaded vertically. On the other side, I CA'ed and polished before I

glued them in (much easier). Other than the CA and polishing on the first side,

no work was done on the rails after being glued in.

|

|

The only problem I see so far is that the

slats are a bit thinner than the wing. Since I made the upper surface match as

is, I will putty the lower surface to match the lower OML of the wing, which

should be fairly easy to do. So far this looks like a very slick piece of

machinery. The only problem I see so far is that the

slats are a bit thinner than the wing. Since I made the upper surface match as

is, I will putty the lower surface to match the lower OML of the wing, which

should be fairly easy to do. So far this looks like a very slick piece of

machinery.

Steven Ellzey Steven Ellzey

Inlet / Fuse Joint

The forward inlet/fuse joint can

be strengthened to reduce distortion during high power static and low

air speed run-ups and to prevent damage while handling the model. This

can be accomplished during construction or on a completed model. The forward inlet/fuse joint can

be strengthened to reduce distortion during high power static and low

air speed run-ups and to prevent damage while handling the model. This

can be accomplished during construction or on a completed model.

Once the

forward inlet duct section has been glued in according to the

instructions, position the fuse nose down onto a flat surface (cover

with wax paper) and pour a mixture of resin and micro-balloons through

the openings of F-1. Once the

forward inlet duct section has been glued in according to the

instructions, position the fuse nose down onto a flat surface (cover

with wax paper) and pour a mixture of resin and micro-balloons through

the openings of F-1.

Use one

and one half ounces of Pacer Finishing Resin mixed with micro-balloons

to form a thickened, but still pourable slurry. Use one

and one half ounces of Pacer Finishing Resin mixed with micro-balloons

to form a thickened, but still pourable slurry.

Allow to cure with fuse in vertical position. Allow to cure with fuse in vertical position.

F-100 Stabilator Control Horns

some were tapped 4-40 vs 5-40

Our vendor for this part misread

the print and we did not catch the mistake prior to shipping some of

these units. Our vendor for this part misread

the print and we did not catch the mistake prior to shipping some of

these units.

Check

that the part in your kit is properly setup for the #5-40 bolts that

mount the pushrods. If it is not, return it for a replacement. If you

have a #38 drill and 5-40 tap, you can correct the part in your shop. Check

that the part in your kit is properly setup for the #5-40 bolts that

mount the pushrods. If it is not, return it for a replacement. If you

have a #38 drill and 5-40 tap, you can correct the part in your shop.

Sorry for

the inconvenience. Sorry for

the inconvenience.

F-100 Wheel Brakes Retention

Note that the wheel brake hub is

retained to the axle with (2) "dog end" set screws that seat into a hole

through the wheel axle and are locked in place with secondary set

screws. Note that the wheel brake hub is

retained to the axle with (2) "dog end" set screws that seat into a hole

through the wheel axle and are locked in place with secondary set

screws.

After

several flights you can check the security of these screws with a 5/64"

hex wrench. After

several flights you can check the security of these screws with a 5/64"

hex wrench.

We

have observed that after about 80 flights on our "D" model, the "dog

end" set screw is slightly bent but still functional. We

have observed that after about 80 flights on our "D" model, the "dog

end" set screw is slightly bent but still functional.

Spare set screw sets are available - a nice

addition to your spare parts kit. Add it to your next order and save on

the postage. Spare set screw sets are available - a nice

addition to your spare parts kit. Add it to your next order and save on

the postage.

Package #5828 contains: Package #5828 contains:

(4) dog end 8-32 x 3/8" (4) dog end 8-32 x 3/8"

(4) set

screw 8-32 x 1/4" (4) set

screw 8-32 x 1/4"

Price:

$4.00 Price:

$4.00

F-100 Slat Servos

JR has

discontinued the 3321 servo that we call for in the instructions for use on the

slats. JR has

discontinued the 3321 servo that we call for in the instructions for use on the

slats.

The

replacement digital variety #3301 are temporarily out of stock. The Airtronics

94141 (metal gear) makes an excellent substitute. Two standard and two reverse

units are required. These servos allow manual operation of the slats. We always

like to see the slats extended for static display. See your Airtronics dealer.

F.T.E. has these units in stock - call 561-795-6600. The

replacement digital variety #3301 are temporarily out of stock. The Airtronics

94141 (metal gear) makes an excellent substitute. Two standard and two reverse

units are required. These servos allow manual operation of the slats. We always

like to see the slats extended for static display. See your Airtronics dealer.

F.T.E. has these units in stock - call 561-795-6600.

BV's new F-100F utilizes

the 94141's on the slats. BV's new F-100F utilizes

the 94141's on the slats.

F-100 Speed Brake / Wheel Brakes mix on the JR

10X

We mixed the speed brake to the wheel brakes and assigned the

control to the Aux 3 channel. We mixed the speed brake to the wheel brakes and assigned the

control to the Aux 3 channel.

The first 90% of side lever travel provides proportional braking for

taxi control. The last 10% activates the speed brake air valve servo control

servo. The first 90% of side lever travel provides proportional braking for

taxi control. The last 10% activates the speed brake air valve servo control

servo.

I prefer

to fly the final approach with the speed brake deployed so that the glide slope

and touchdown point is very precisely controlled with power. Touching down with

the brakes "on" will yield a short roll out of about 200ft. If this is not

desired, move the Aux 3 lever just a bit prior to touchdown to release the

"full on" brakes and hold the nose high for a full flare landing. I prefer

to fly the final approach with the speed brake deployed so that the glide slope

and touchdown point is very precisely controlled with power. Touching down with

the brakes "on" will yield a short roll out of about 200ft. If this is not

desired, move the Aux 3 lever just a bit prior to touchdown to release the

"full on" brakes and hold the nose high for a full flare landing.

For Futaba 9ZAP users

there is a device called the electronic switch that will help free up a

channel. BVM rep Paul Bageman has some experience with this item. For Futaba 9ZAP users

there is a device called the electronic switch that will help free up a

channel. BVM rep Paul Bageman has some experience with this item.

Landing Heavy

and Fail Safe setup

I had one occasion at Jets over Deland (Jan

'01) where the radio was indicating fail safe conditions shortly after

take-off. I had one occasion at Jets over Deland (Jan

'01) where the radio was indicating fail safe conditions shortly after

take-off.

I always

set the fail safe as follows: I always

set the fail safe as follows:

Engine to idle, gear down, and a slight amount of up

stab. Engine to idle, gear down, and a slight amount of up

stab.

The

"Hun" was on the downwind leg when I saw the gear extend, so I immediately

entered the landing pattern, dirtied up and set the power appropriately for a

heavy landing. The

"Hun" was on the downwind leg when I saw the gear extend, so I immediately

entered the landing pattern, dirtied up and set the power appropriately for a

heavy landing.

With about 90% of the 4.8 Liters of fuel remaining the slatted wing

handled the extra 5-6 pounds of fuel (above a normal landing) very well - just

keep the power on. With about 90% of the 4.8 Liters of fuel remaining the slatted wing

handled the extra 5-6 pounds of fuel (above a normal landing) very well - just

keep the power on.

This experience confirms that we can add a few extra pounds worth of

missiles and bombs and enjoy the ultimate airborne appearance. Plenty of

reliable power is all that is needed. This experience confirms that we can add a few extra pounds worth of

missiles and bombs and enjoy the ultimate airborne appearance. Plenty of

reliable power is all that is needed.

Stab Servos - shim

To keep the servo cases from interfering with

the bottom fuse skin, it is necessary to add 1/8" ply shims to the inboard

faces of the stab servo mounts. BV's model has the bottom of the servo cases

protruding very slightly to keep a close check on servo temps after flight. So

far no problems, holes in the bottom of the fuse are not

necessary. To keep the servo cases from interfering with

the bottom fuse skin, it is necessary to add 1/8" ply shims to the inboard

faces of the stab servo mounts. BV's model has the bottom of the servo cases

protruding very slightly to keep a close check on servo temps after flight. So

far no problems, holes in the bottom of the fuse are not

necessary.

Stab Control Yoke

A very few parts may have been shipped out

with 4-40 threaded holes vs. the correct 5-40 threads. Contact BVM if you

received a 4-40 set. A very few parts may have been shipped out

with 4-40 threaded holes vs. the correct 5-40 threads. Contact BVM if you

received a 4-40 set.

3-View Drawings

We used the drawings from the War Paint Series

#4 booklet. 11" x 17" copies of the top, side and front view of the F-100D are

available from BVM. We used the drawings from the War Paint Series

#4 booklet. 11" x 17" copies of the top, side and front view of the F-100D are

available from BVM.

Contact Us

All graphics, photos, and text

Copyright 2018 BVM, Inc.

Use of graphics or photos without written permission from

BVM is

strictly prohibited.

|

F-100

customers have been very pleased with what you see here. It is technically

accurate and very detailed. The casting resin system is the best we have seen.

The parts are not warped and are reasonably light in weight. The instruction

package shows step-by-step assembly and painting, even including the correct

F.S. (Federal Standard) numbers.

F-100

customers have been very pleased with what you see here. It is technically

accurate and very detailed. The casting resin system is the best we have seen.

The parts are not warped and are reasonably light in weight. The instruction

package shows step-by-step assembly and painting, even including the correct

F.S. (Federal Standard) numbers.

The F-100 was the first

operational jet fighter for the U.S. Air Force that was designed to operate

supersonic. Experienced gained by the early X plane development programs

allowed North American to design and build very thin, low drag flying surfaces

that could also withstand the stresses of MACH 1 plus flight.

The F-100 was the first

operational jet fighter for the U.S. Air Force that was designed to operate

supersonic. Experienced gained by the early X plane development programs

allowed North American to design and build very thin, low drag flying surfaces

that could also withstand the stresses of MACH 1 plus flight. edges and

the overall thinness ratio of the surfaces.

edges and

the overall thinness ratio of the surfaces.

Each leading edge slat rail has

been custom fitted at the factory into the precision machined tracks that are

built into the wings.

Each leading edge slat rail has

been custom fitted at the factory into the precision machined tracks that are

built into the wings.