July

'01

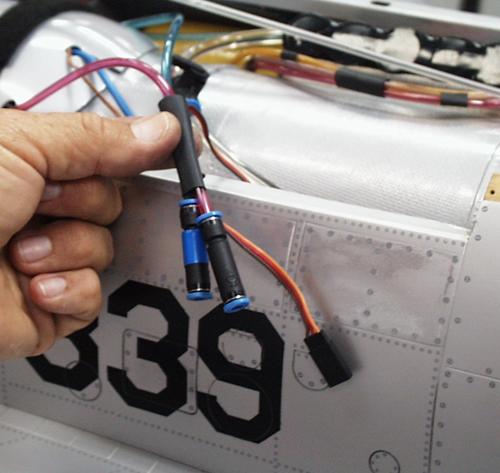

The following information and photo's will help

clarify a few fine points of gearing up the F-100D.

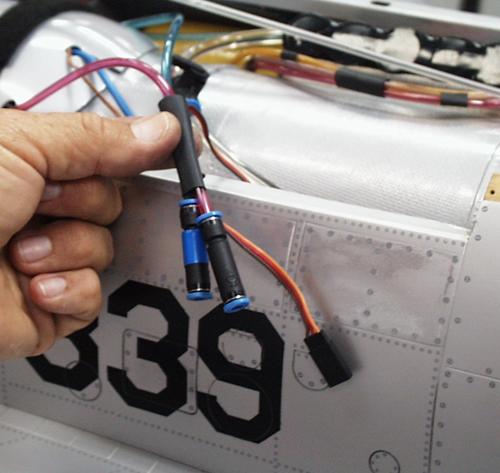

Stabilator

servo wiring

Locate the "Y" harness close to the

receiver and be able to access the two connections to the 36" leads. Before

each flying session, disconnect one at a time to ensure that both 8411 servos

are functioning. Do not use servos with less power than 150oz/inches of

torque.

Speed Brake

control

The prototype has the speed brake

activated by the same channel (Aux 3, JR) as the wheel brakes. The last few

degrees of travel of the slide switch on the transmitter commands the speed

brake to open.

Approaches and landings on short runways are accomplished

with the speed brake deployed and the brakes full "on". Landing roll out will

be about 200ft. Tire wear is not excessive.

Fuel

System

Incorporate a BVM Ultimate Air Trap

(U.A.T.) into the fuel system. Place it in the fuse on the left side of the

inlet duct. Rig the 16oz. header tank as a 2 line system and fill through the

3rd line on the U.A.T.

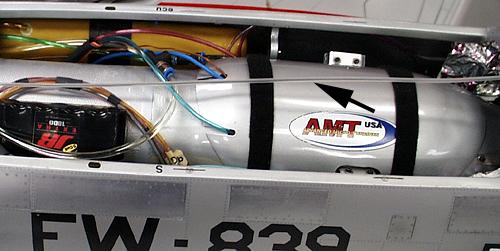

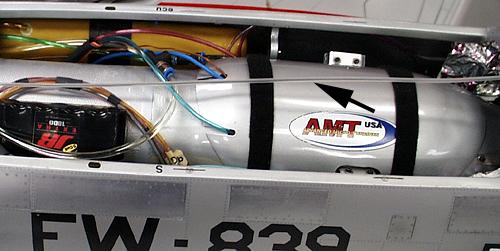

Retract

System

Add a 2nd air tank (BVM #4204) to the

retract system. "T" it into the other tank to increase the volume of air

available to operate the landing gear.

Use a BVM modified Robart 4-way

valve marked "Retracts" or "Gear" to control the system.

Retracts and

Door Cycler

Use the programmable unit available

from Mini Hobby Atl. or BVM. The time between the gear "up" command and the

door closing should be 6-7 seconds to allow for air load delays on the landing

gear. The door command on the down cycle can be 4 to 5 seconds.

It is a

good procedure to check the gear operation before each flight. Observe that

there are no severe air leaks in the up or down position. A fill pump with a

guage will assist here.

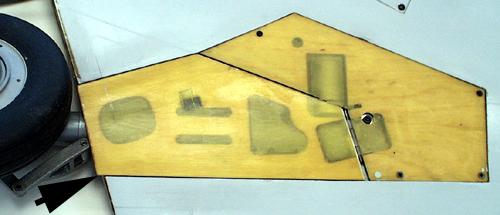

Main wheel well

door stops

The edges of the main wheel well doors

are thicker than the fuse skin. Therefore, the poly ply strips on the fuse

opening that serve as seats for the doors, must be offset from the inside fuse

skin accordingly. Use strips of 1/64" ply (cross grain) to

accomplish.

Forward inlet

glue joint

Improper handling of the forward end

of the fuse can cause the glue joint between the front of the fuse and the

inlet to fracture. Subsequent full power run-ups may cause the inlet to deform.

Check this glue joint often and look down the inlet occassionally during a

ground run up. The pressure drop in the inlet during forward flight is

considerably less.

|

JR 1800 mah

5-cell pack powers the radio system - charge after 2 flights with Graupner MC

Ultra Duo plus. Antenna is on center and suspended 1" or more off the top of

the bypass, make notch in aft flange of hatch as

necessary.

|

|

Start air,

propane and data terminal connections for AMT are accessed through main

hatch.

|

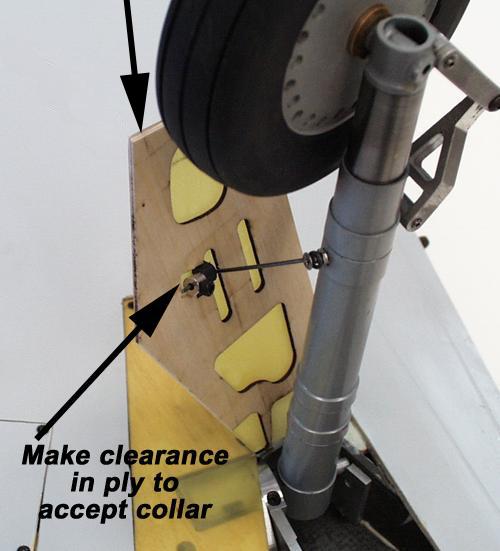

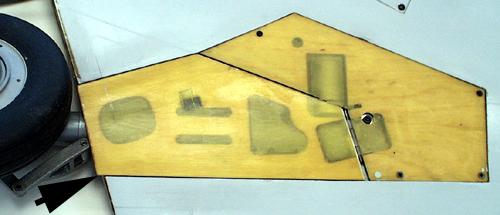

Bevel this edge if

necessary to clear tire

|

|

|

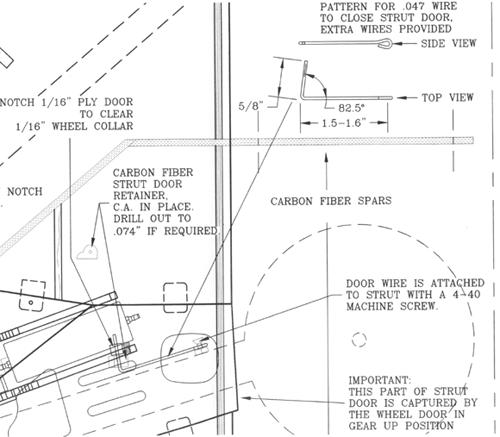

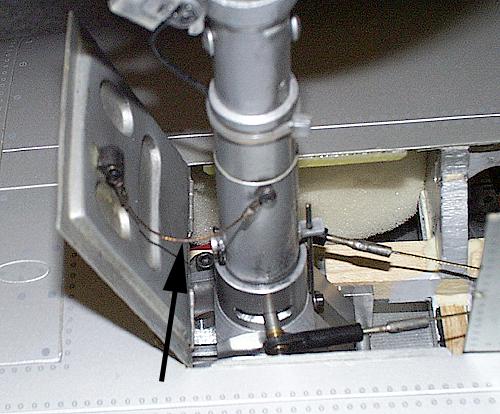

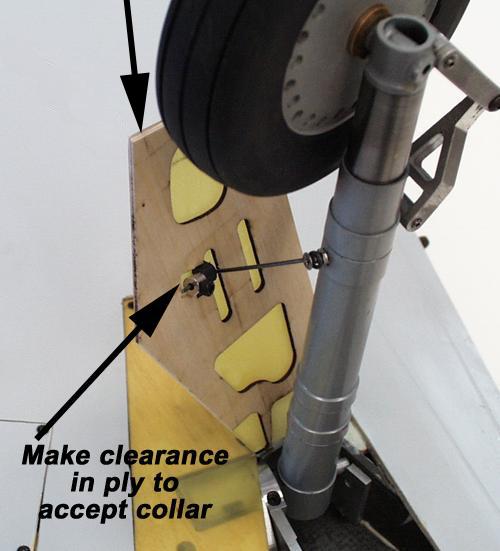

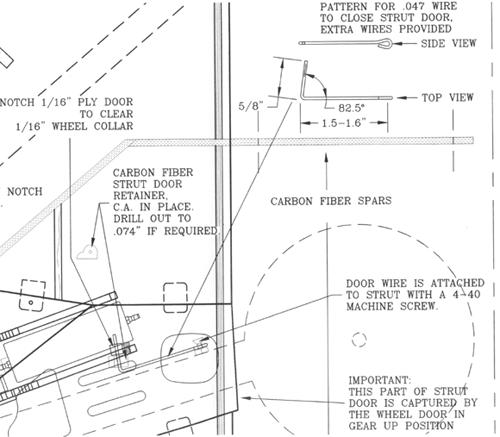

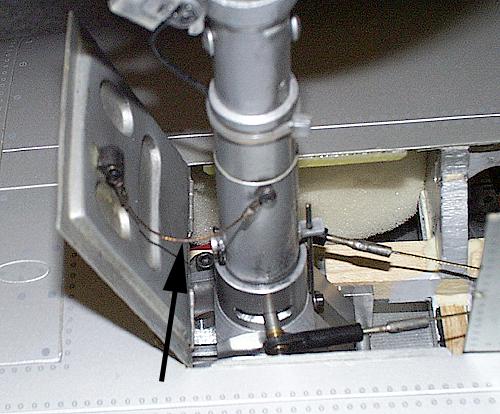

| Main strut

door attachment is by .047" wire. Loop end attaches to strut. Bend out board

end and attach to CF part with small wheel collar. Fine tuning of outboard end

angle determines door closing. Drilling hole in CF part oversize may assist.

Bottom edge of strut door will just about touch the tire during up cycle.

Relieve door if necessary. The brake line is taped to strut and routed through

the axle. Secure all air lines to not interfere with retract

action. |

Lower aft

end of door must extend into fuse, thus, the wheel well door traps it in place

for flight. |

|

|

1/32" nose

gear steering cables use ball/socket linkage on both ends. They are kept out of

way of retracting strut with (2) light rubber

bands.

|

|

The nose

gear fwd door is attached to the strut with fishing line cable and 2 crimps.

One end is secured to the CF strut door attachment and the other is secured to

the strut with button head panel screws.

|

|

| Molded

refueling probe mount is attached to the bottom of the right wing. |

F-100 customers who need any of these parts to

complete the gearing-up process, please let us know.

Contact Us

All graphics, photos, and text

Copyright 2016 BVM, Inc.

Use of graphics or photos without written permission from

BVM is

strictly prohibited. |