|

This "Tips and How To's" Series on Model Turbine

Fuel Systems may help you avoid some of the common, and

not so common, items that can cause a "Flame-Out".

A proper fuel system installation, periodic

maintenance checks, and certain precautions when

handling and storing your turbine powered model are

necessary for reliable engine operation.

Clunks must stay in the fuel

For jet models that have a large unbaffled tank as the

primary fuel storage area, sometimes the clunk can get

stuck in the front of the tank because of transporting

or storing the model nose down. Possibly, a landing

that ends up with the model flipping over can also force

the clunk forward. The flexibility of the tubing that

serves to position the clunk in the tank can also

contribute to the clunk getting stuck in the front of

the tank. To check that the clunk is not lodged forward,

hold the nose of the model up and shake it sideways such

that you can hear the clunk tapping the AFT side wells

of the tank. If it is not obviously functioning properly,

remove the tank and check it out.

Festo Fittings

precautions

Use them on the positive pressure side of the pump

only and avoid sharp bends in the tubing close to the

fitting. On the positive pressure side, you can spot a

small leak, on the suction side, if there is less than a

perfect seal, air will get into the fuel system.

In-Line Fuel Filter

Most fuel filters utilize a fine mesh screen and an

"O" Ring seal. This allows occasional disassembly and

cleaning. The Fuel Filter should be placed downstream

of the Fuel Pump and ALWAYS oriented vertical to the

model's longitudinal axis. The vertical orientation will

allow an initial run-up bubble to dislodge before

your first aerobatic maneuver.

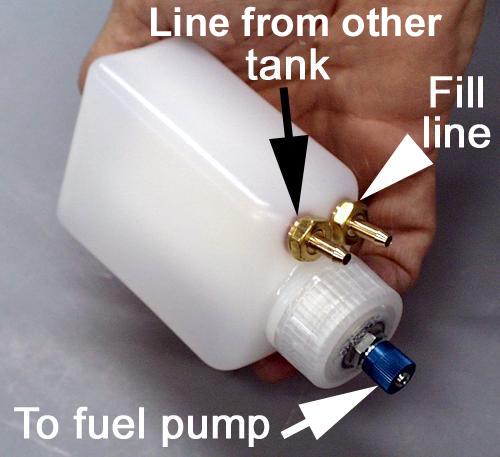

The Ultimate Air Trap - U.A.T.

A properly designed and manufactured U.A.T. is a vital

part of any turbine fuel system. The container should

be translucent so that you can visibly determine how

much air vs. fuel is present, before and after a flight.

A container that is a bit flexible will also reveal

supply and demand pressures during the fueling process

and engine fuel pump demands during high power settings.

Of course, the BVM U.A.T. has all of these features

and a unique porous sack inside that can deliver bubble

free fuel even if the 4oz. container has trapped so much

air that it occupies more space than fuel.

BVM has supplied U.A.T.'s to the turbine industry

since 1997. BVM offers the U.A.T. in its original

format that is ideal for engines up to 140 Newton's of

thrust, and a Hi-Flow version for the larger engines.

See www.BVMJets.com/HiFlow

Stay

tuned for more fuel system Tips and How To's. |